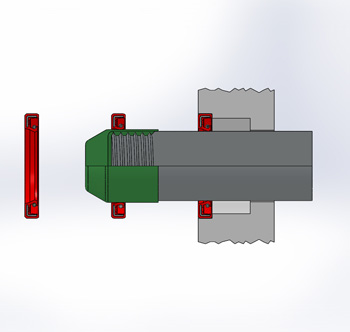

In order to efficient operation of the sealing element at the desired performance, it is important to assemble it under suitable conditions. Leakage can occur when a sealant design and material is not properly installed. The following steps should be followed for a proper installation;

Unsuitable assembling

.jpg)

When designing the assembling apparatus, the outer diameter of the apparatus should not be much smaller than the oil seal outer diameter. Otherwise, the sealing element will be deformed during assembly. The dimensional change caused by the deformation in the sealing lip causes leaks.

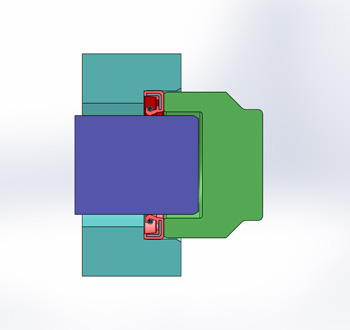

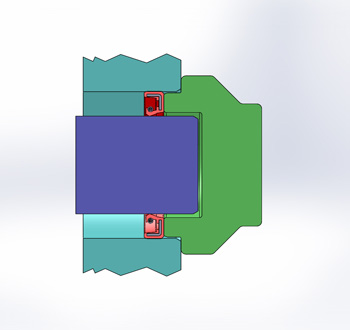

Unsuitable assembling

Sealing Elements with a Specific Supporting Surface

Sealing Elements without a Specific Supporting Surface

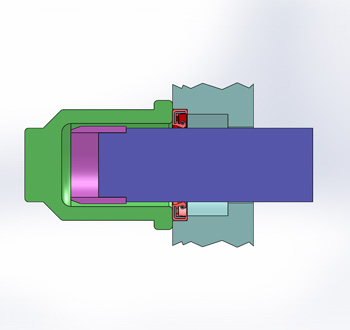

Using the Ring

Sealing Elements Damaging the Working Surface