Dynamic sealing in rotary shaft seals; It occurs by hydrodynamic effects in the thin film layer formed by the hydrostatic pressure of the fluid under the sealing lip, by pumping the leaked fluid back into the system.

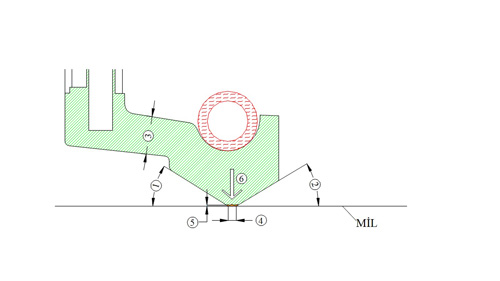

Effective Parameters in managing these hydrodynamic movements; lip angles (1-2), thickness of the flexible part of the lip (3), contact flatness formed by the lip on the shaft (4), thickness of the film layer (5), and the radial load applied by the spring and rubber to the shaft.

FEKO; applying the knowledge of sealing; manages these parameters with the standards it establishes based on technical research, analysis and test.

Geometric designs of other sealing element types; are determined by engineering calculations performed in the light of static and dynamic sealing mechanisms, taking into account the expected performance conditions.